Case Study – Material Handling

Q: Why are material handling workers suffering so many injuries?

A global automotive manufacturer was experiencing a high rate of back and shoulder injuries. The injury rate needed to come down. The company had implemented several measures, including a modified duties program, but injury rates remained high. Workers also deemed the program unsatisfactory. The company was determined to understand the root cause of injury and to improve the effectiveness of its program.

A: Good intentions

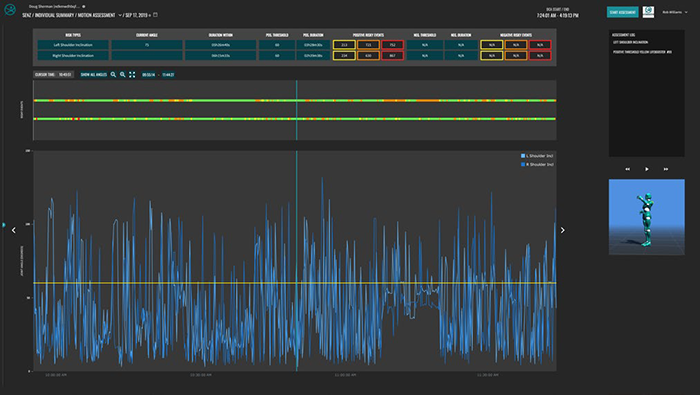

The work was labor-intensive, consisting of repetitive reaching, lifting, bending, and over shoulder work. We assessed a group of workers using motion-tracking wearable sensors. Then we analyzed the data using our predictive analytics platform, Senz™. The analysis showed that the modified duties program did in fact reduce the risk for shoulder strain. But it also uncovered that the program significantly increased back risk exposure by 80%. The analysis also uncovered that the loading bins used by most workers were leading to awkward postures that increased the risk of injury.

Outcome:

Based on the data, our customer developed an intervention strategy to improve the modified duties program with better back and shoulder support. Adjustments were also made to the physical layout of the operation. The company made changes including raising the parts loading bin and implementing bins with side loading doors to reduce lifting movements. Subsequent Senz assessments were conducted to quantify the success of the intervention strategy.

Elevated Shoulder Risk, Attention Required

- Total assessment time: 8 hours, 55 minutes

- Percent time in high risk: 39% left shoulder, 30% right shoulder