Geometry Matters: A New Way of Reducing Error Rates in Collecting Worker Risk Data

Forward-thinking companies are turning to new technologies to improve and innovate their safety systems. In a survey conducted by leading research and advisory firm, Verdantix, 60% of respondents viewed innovation as a high priority in their environment, health, and safety (EHS) function (Velasco, 2019). As the demand for technology-driven solutions increases among safety and health professionals, many buyers are leaning toward multi-point sensor systems to strengthen their EHS performance in the workplace.

Considering risk assessments alone, the growing interest in technological solutions reflects the superior data quality that modern approaches to data collection have to offer. Many organizations still rely on traditional methods of evaluating risk. However, research has shown that even when well-trained assessors conduct observational risk assessments, these methods have up to 30% error rates, making the outputs unreliable and inaccurate (Diego-Mas et al., 2017). In contrast, the implementation of multi-point wearables to conduct digitized risk assessments heightens the quality and practicality of an organization’s risk management process without compromising operational excellence.

One commercial solution that provides greater breadth and depth in terms of the quality of data collected is a multi-point sensor system. Working as a system of remotely-connected wearables that “broaden the scope of data recorded,“ multi-point sensor systems allow, “EHS decision makers to better attribute external factors to at-risk behaviors,” enabling the application of improved risk control and mitigation strategies (Brown et al., 2021). In addition to improving the breadth and depth of data captured, multi-point sensor systems deliver advanced risk data analytics that objectively quantify risk exposure, in comparison to observational tools which rely on subjective estimates of risk exposure. Ultimately, a multi-point sensor approach to evaluating worker risk revolutionizes EHS risk assessments by providing comprehensive empirical insights into worker safety.

Challenges of Traditional Assessment Methods

When comparing traditional risk assessment practices to multi-point wearables, observational approaches pose several challenges to EHS and ergonomics professionals.

One major challenge of observational risk assessments is their proclivity to subjectivity errors. For example, due to the qualitative nature of the data being collected, insights derived from this type of assessment practice would only be as reliable as its source. These subjectivity errors may be driven by lack of training, insufficient experience using the analysis tool, or insufficient sampling which impacts the accuracy of the data collected. Therefore, if data captures were to be exposed to an assessor’s biases or prejudices, the data being collected would have questionable reliability.

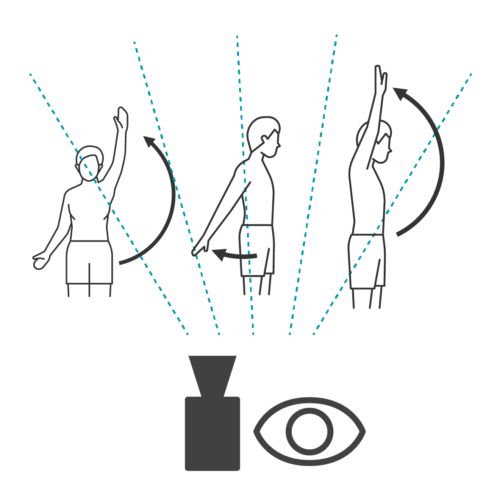

Furthermore, In the case of risk assessments being recorded, a video’s single-point perspective leads the capture to be susceptible to high error rates in data collection as a result of obstructions of the work environment to a camera’s line of sight. Other factors such as camera instability, different file types, and parallax recording errors are other major limitations regarding recorded risk assessments.

Traditional Risk Assessments:

2D Visual Plane

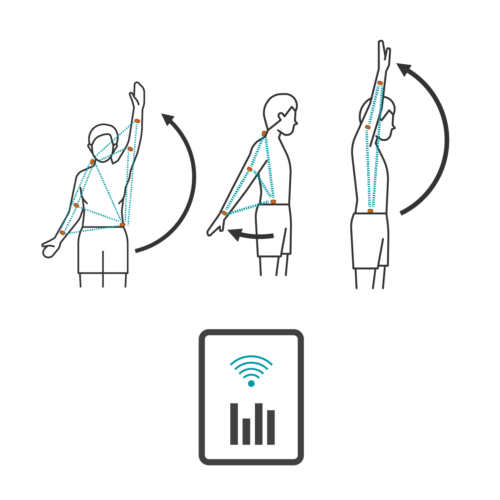

Advantages of Multi-Point Sensor Systems

In contrast, multi-point sensor systems offer major advantages to cover these bases. Some of these advantages include:

Multi-Point Sensor Risk Assessments:

3D 360° Digital Plane

Overall, the value of multi-point sensor systems lies in the fact that they are an all-in-one assessment solution that actively measures different types of risk and body segments while facilitating risk identification with greater clarity through deeper, more granular data. Additionally, multi-point sensor systems are an exhaustive means of capturing occupational risk as they provide the ability to view data from the perspective of an individual employee, workgroup, task, and even across an organization. As no company, nor worker is the same, organizations may look toward the use of multi-point sensor systems to provide a human-centric approach to risk assessments that considers the variable nature of safety in the workplace.

To learn more about multi-point sensor systems when compared against single-point sensor systems, how risk is not uniform, and why geometry matters, visit: https://hubs.la/Q01nwzvJ0

Brown, T., & Pennington, B. (2021). (rep.). Strategic Focus: The Role Of Technology In Behaviour Based Safety Management Programmes. Verdantix. Retrieved September 6, 2022, from https://www.verdantix.com/report/environment-health-safety/strategic-focus-the-role-of-technology-in-behaviour-based-safety-management-programmes.

Diego-Mas, J.-A., Alcaide-Marzal, J., & Poveda-Bautista, R. (2017). Errors Using Observational Methods for Ergonomics Assessment in Real Practice. Human Factors, 59(8), 1173–1187. https://doi.org/10.1177/0018720817723496.

Velasco, I. (2019). (rep.). Green Quadrant Digital EHS Services 2019. Verdantix. Retrieved August 23, 2022, from https://www.verdantix.com/report/environment-health-safety/green-quadrant-digital-ehs-services-2019.

Join Our Mailing List